Polyamide 6/10 is made by polycondensing hexamethylene diamine and sebacic acid, which is extracted from the seeds of the castor oil plant. PA 6/10 can be said to come partly from a renewable resource since over half its weight is derived from sebacic acid. Polyamide 6/10 are bio-based polyamides and It is also called as Nylon-6/10. It is a semi crystalline polyamide commonly used in monofilament form in applications such as bristles and brushes, due to its low moisture absorption compared to other nylons, it retains its properties better when wet. Polyamide 6/10 is made from decanedioic acid and 1, 6 diaminohexane. Nylon 6/10 have been approved by the FDA as indirect food additives used for food contact surfaces. The polyamide 6/10 is used primarily as bulking and opacifying agents in cosmetic formulations.

Polyamide 6/10 Market Outlook

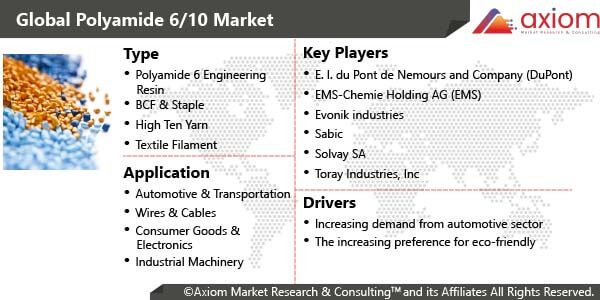

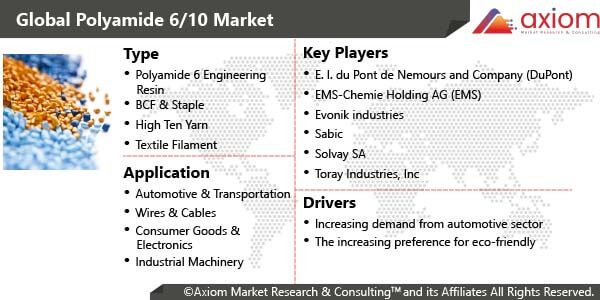

The global polyamide 6/10 market is primarily driven increasing demand from automotive sector. The demand for environment friendly polyamides which are also called as bio-based polyamides is increasing owing to the increasing preference for eco-friendly and sustainable solutions. Moreover, rapidly evolving automobile, electrical & electronics, and textile sectors are projected to boost the demand for the product in the next few years. However, high cost of polyamide 6/10 and easy availability of substitute are the major factor anticipated to hinder the growth of the market during the forecast period.

Polyamide 6/10 Market Segmental Overview

Global polyamide 6/10 market report is segmented into, application and geography.

Polyamide 6/10 Market by Application

By application, polyamide 6/10 market is segmented into automotive & transportation, industrial application and consumer goods & electronics. The automotive and transportation industry majorly dominated the consumption of polyamide 6/10. The automotive & transportation segment in terms of value accounted for highest market share 55% and is anticipated to maintain its dominance over the forecast period, followed by industrial application and consumer goods & electronics segment.

Polyamide 6/10 Market by Geography

Based on geography, the global polyamide 6/10 market is segmented into North America, Europe, Asia Pacific and rest of the world regions, which include Latin America and Middle East & Africa. North America accounted for second largest market share in the global polyamide 6/10 market and is expected to register high growth due to increased rate of adoption in end-use industry. The rapid growth in North America is attributed to rise in domestic consumption and investment by the corporate sector. Moreover, Asia-Pacific is estimated to dominate the global polyamide 6/10. This growth can be attributed to the presence of emerging economies such as China, India, Taiwan, and others as well as the growth in end user industries such as automotive and healthcare.

Polyamide 6/10 Market Key Players

The key companies operating in the global polyamide 6/10 are E. I. du Pont de Nemours and Company (DuPont), EMS-Chemie Holding AG (EMS), Evonik industries, Sabic, Solvay SA, Toray Industries, Inc and Shakespeare Company, LLC. Polyamide 6/10 is manufactured using 60% of renewable raw material like castor oil which allows the manufacturers to meet the increasing demand for environment friendly products. Research and development activities are carried out by key player for increasing use of bio polyamides in the automotive sector. Moreover, several application development projects are currently underway what aims at striking an ideal compromise between technical and ecological goal. The global polyamide 6/10 market is primarily driven increasing demand from automotive sector. The demand for environment friendly polyamides which are also called as bio-based polyamides is increasing owing to the increasing preference for eco-friendly and sustainable solutions

Polyamide 6/10 is produced using a plant-based raw material sebacic acid which synthesised from castor oil and obtained from the seeds of Ricinus communis, the castor oil plant. the sebacic acid used for production of PA 610 is derived from a renewable resource. Polyamide 6/10 are long-lived, durable and can be used in demanding applications, e. g. in the automotive industry. They products are typically applied in injection moulding, fibres, powders, extrusion, and films. It is mostly used in automotive application owing to its characteristics like high resistance to hydrolysis which is vital importance for cooling-system components of cars and goods vehicles. By application, polyamide 6/10 market is segmented into automotive & transportation, industrial application and consumer goods & electronics. The automotive and transportation industry majorly dominated the consumption of polyamide 6/10. The automotive & transportation segment in terms of value accounted for highest market share 55% and is anticipated to maintain its dominance over the forecast period, followed by industrial application and consumer goods & electronics segment. Based on geography, the global polyamide 6/10 market is segmented into North America, Europe, Asia Pacific and rest of the world regions, which include Latin America and Middle East & Africa. North America accounted for second largest market share in the global polyamide 6/10 market and is expected to register high growth due to increased rate of adoption in end-use industry. The rapid growth in North America is attributed to rise in domestic consumption and investment by the corporate sector. The key companies operating in the global polyamide 6/10 are E. I. du Pont de Nemours and Company (DuPont), EMS-Chemie Holding AG (EMS), Evonik industries, Sabic, Solvay SA, Toray Industries, Inc and Shakespeare Company, LLC. Polyamide 6/10 is manufactured using 60% of renewable raw material like castor oil which allows the manufacturers to meet the increasing demand for environment friendly products.

Why to buy this report:

- The report offers changing market dynamics in the polyamide 6/10 industry, presenting historical, current and projected market size in terms of value (USD Million)

- The research study provides an in-depth analysis of the industry value chain focusing on the peer and parent markets of polyamide 6/10, such as polyamide market, high performance polyamide market, polyamide 12 market, etc.

- It presents a comprehensive assessment of geographical regions exhibiting promising growth, potential and niche segments, and a neutral perspective on the polyamide 6/10 market performance

- The report also offers strategic recommendations in key business segments based on the market estimations and competitive landscape, mapping the key common trends of polyamide 6/10 market