MARKET OVERVIEW- GLOBAL HEAVY DUTY CONNECTOR MARKET

A heavy duty connector is a device that allows electrical current to be supplied to a device that provides power for operation. It functions as an essential power transmission device widely used in several industrial applications. Heavy duty connectors consist of an insulating sleeve and a number of terminals that improve its applications because it is able to deliver the same power through multiple terminals. Heavy duty connectors play a major role in automotive, consumer electronics, data communication, and many other industries, expanding the scope of the study with significant growth in the global market. The sudden onset of the COVID-19 pandemic has definitely brought several sectors to a standstill, leading to an increase in the number of work-from-home options around the world. This has led to an increase in demand for consumer electronics such as tablets, laptops, and smartphones, with the demand for heavy duty connectors increasing globally during the forecast period. Aerospace and military applications require high-speed and compact heavy duty connectors to connect devices to power in smaller spaces, which helps maintain safety and provides adequate performance for adaptive control systems, automatic emergency braking, etc. On the other hand, rapid automotive production in developing countries with growing populations has led to the growing adoption of heavy duty connectors in the automotive sector. Connectors play a major role in providing sufficient power to automotive engines or devices and hence are expected to boost market growth in the coming years.

MARKET DRIVERS

Heavy duty connectors are widely used in renewable energy applications due to their high connecting capability in harsh environments. Governments around the globe are investing heavily in renewable energy sources due to energy shortages. Renewable energy provides clean and safe energy without any CO2 emissions. Due to these growing investments, the consumption of high-performance heavy-duty connectors in renewable energy generation is increasing. According to the IEA (International Energy Agency), the year-on-year growth of renewable energy has witnessed significant growth. The growth rate in 2019 was around 3%, and has increased to 6%, and 10% in 2020, and 2021, respectively. Moreover, the growing importance of industrial safety is another important factor driving the growth of the global heavy-duty connectors. In addition, governments have set some regulations and safety standards that players must adhere to, forcing them to use high-strength heavy-duty connectors in the industry.

Automation is gaining traction in a wide range of industries worldwide to improve the functionality of equipment such as industrial robots; developing countries such as China, Japan and South Korea are implementing various automation solutions. Heavy-duty connectors, also known as high-duty sockets, are commonly used in electrical and signal connections in construction machinery, textile machinery, packaging and printing machinery, tobacco machinery, electric locomotives and petrochemical electrical equipment. In addition, these connectors are a better solution for the assembly of machines and equipment, which is safe, time-saving and straightforward. Thus, the rapid adoption supports the demand for heavy duty connectors in the industrial automation industry and propels the heavy duty connectors market forward

MARKET OPPORTUNITIES

Increasing adoption of heavy-duty connectors in data centers. The companies have been able to improve their internet capabilities and thus improve signal connectivity in their organization. The use of heavy duty internet connectors in data centers provides high-speed transmission of huge amounts of data, which helps increase work productivity. With the help of these connectors, data centers are able to meet the demands of high-end and data-intensive applications that offer high performance, thus providing opportunity for the growth of the heavy-duty connectors market.

MARKET RESTRAINTS

Lack of skilled manpower and technological knowledge in underdeveloped and developing countries expected to hamper the growth rate of the market. And a lack of strong IT infrastructure in underdeveloped economies will also hamper the growth rate of the market.

MARKET GROWTH CHALLENGES

High cost associated with heavy duty connector’s products. This has resulted in reluctance among consumers to purchase premium heavy duty connectors products. Hefty costs of heavy-duty connectors coupled with high short circuits that can regularly damage the product in emerging economies are the factors challenging the growth of the heavy-duty connectors market.

CUMULATIVE GROWTH ANALYSIS

The report provides an in-depth analysis of the global heavy duty connector market, including market size, and compound annual growth rate (CAGR) for the forecast period of 2023-2029, considering 2022 as the base year. The growing demand for heavy-duty connectors in the renewable energy sector is expected to witness a growth at a specific CAGR from 2022-2029.

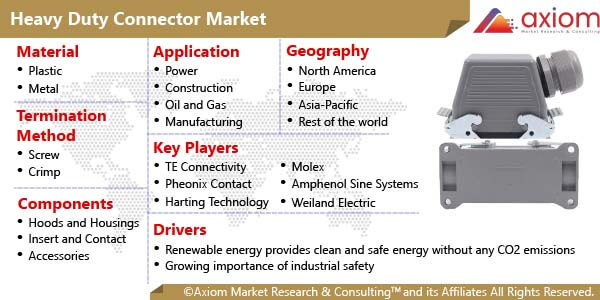

HEAVY DUTY CONNECTOR MARKET SEGMENTAL OVERVIEW

The global heavy duty connector market consists of different market segments like material, termination method, components, application and geography.

HEAVY DUTY CONNECTOR MARKET BY MATERIAL

The heavy duty connector market finds key mounting types like:

The plastic segment is expected to dominate the market over the forecast period. Plastic heavy-duty connectors are lightweight, which is crucial for applications that require minimal weight. Due to its lightweight, it can be used in construction equipment, military vehicles, automated factories, and other applications. Compared to metal connectors, plastic heavy-duty connectors are well suited for outdoor applications as they provide better moisture resistance and are more resistant to saltwater than their metal counterparts while also being more UV-stable. Due to these factors, the plastics segment is expected to witness high growth over the forecast period.

HEAVY DUTY CONNECTOR MARKET TERMINATION MATHOD

The heavy duty connector market finds key termination methods like:

The screw segment is expected to dominate the market over the forecast period. A wire termination is the work performed to the end of a wire that allows it to connect to a device (connector, switch, terminal, etc.). Screw terminals are low in cost when compared to other types of connectors, and can be readily designed into products for circuits carrying currents of from a fraction of an ampere up to several hundred amperes at low to moderate frequencies. The terminals easily can be re-used in the field, allowing for the replacement of wires or equipment, generally with standard hand tools. This facilitates the use of the screw terminal method in a wide range of applications. Due to these factors, the screw segment is likely to witness high growth over the estimated time period.

HEAVY DUTY CONNECTOR MARKET COMPONENTS

The heavy duty connector market finds key components like:

- Hoods and Housings

- Insert and Contact

- Accessories

The hoods & housing segment is expected to dominate the market over the forecast period. Hoods and housings are used in conjunction with contact inserts to make up a complete heavy-duty power connector. The protective mounting shell is usually made of cast aluminium, and the surface of the shell is treated with powder coating or self-extinguishing thermoplastic material. The seal between the housings allows the connector housing to be protected from mechanical shocks. Therefore, the hoods and housings are anticipated to witness high growth over the forecast period

HEAVY DUTY CONNECTOR MARKET APPLICATION

The heavy duty connector market finds key application like:

- Power

- Construction

- Oil and Gas

- Manufacturing

- Others

The manufacturing segment is expected to dominate the market over the forecast period. In the manufacturing sector, heavy-duty connectors are widely used in a wide range of applications. It includes construction machinery, textile machinery, packaging and printing machinery, tobacco machinery, robotics, rail transit, hot runners, power, automation, etc. for electrical and signal connections. The manufacturing segment is expected to lead the market over the forecast period due to high growth in the manufacturing sector. Furthermore, increasing investments in the manufacturing industry along with the expansion of the automation sector. For instance, in February 2022, Emerson, the technology, engineering and Software Company, announced the opening of a new integrated manufacturing facility at Mahindra World City. Further, the launch of new production units is expected to stimulate the demand for heavy-duty connectors during the estimated time period.

HEAVY DUTY CONNECTOR MARKET BY GEOGRAPHY

The heavy duty connector market is studied for the following region:

- North America

- Europe

- Asia Pacific

- Rest of World

The Asia-Pacific region is fastest growing region for heavy-duty connectors market and will continue to flourish in the dominance trend during the forecast period due to rapid industrialization, widespread adoption of automation solutions, and competitive pressure to achieve operational efficiency. The Asia-Pacific region will continue to experience significant gains over the forecast period. The reason is the growing expenditure on the development of IT infrastructure and the growing number of small businesses.

COVID-19 IMPACT ANALYSIS ON THE GLOBAL HEAVY DUTY CONNECTOR MARKET

The COVID-19 pandemic is expected to have a significant impact on the growing market for heavy duty connectors. The demand for heavy duty connector products has significantly decreased owing to the lower production of oil and gas, manufacturing projects, and others. For instance, global electricity generation has increased significantly during the pandemic, reaching around 27,037 terawatt hours in 2019, which decreased to 26,889 terawatt hours in 2020. The reduced electricity generation has directly affected the demand for heavy duty connectors during the pandemic. Also, the outbreak of COVID-19 has affected major industries overall, among sectors such as oil and gas, and manufacturing, by hindering various industrial operations and disrupting the supply chain hence, the heavy-duty connectors market is expected to witness a decline in revenue growth.

COMPETITIVE LANDSCAPE ANALYSIS

The competitive landscape analysis of the heavy-duty connector market is primarily focused on expanding the global growth of the heavy-duty connector market with new technology innovation, business expansion, and the increasing presence of a range of manufacturers operating in heavy duty connector market has led to the growing demand for the market.

The key players studied in the market are

- TE Connectivity

- Phoenix Contact

- Harting Technology

- Weidmuller Interface

- Molex

- Amphenol Sine Systems

- Weiland Electric

- IIT Cannon

- ODU

- Lapp Group

- Smiths Interconnect

- F. Walther Electric Corp

- China Utility Electrical

- Bulgin

- Degson Electronics Co., Ltd.

- Indo Electricals

- Schaltbau

- Ningbo Oukerui Connector

- FC Lane Electronics Ltd

RECENT DEVELOPMENT:

December 2021: Renu Electronics has proclaimed the acquisition of phoenix contract HMI IPC expertise GmbH to form Renu Electronics GmbH.

April 2019: Igus introduced prepared to connect control with heavy weight duty conductors in india for substantial industrial requests