Medical device contract manufacturing refers to the process by which a manufacturer produces medical devices or components of medical devices which are then sold by another company. Medical device contract manufacturers may specialize in a particular process or activity and can make suggestions based on their manufacturing knowledge. Customers, clients, and inventors of medical devices can benefit from services such as product design and development, process validation and verification, production, or highly specialized manufacturing, and packaging. They can also keep hold of items supply and delivery to the end customer. With the rising geriatric population and increased life expectancy is boosting the growth of the market. Also increase in healthcare expenditure with rising patient awareness is also contributing to the growth of the market.

Market Dynamic- Asia Pacific Medical Device Contract Manufacturing Market

Increased demand for medical devices as a result of improved healthcare infrastructure and lower raw material costs is driving the growth of medical device contract manufacturing market. The increasing adoption of technologically advanced products is propelling the market growth. The medical device contract manufacturing industry has been impacted due to the emergence of COVID-19 as the demand for medical equipment for elective treatments has decreased, but demand for medical devices such as ventilators and respirators has increased, boosting the market's growth prospects. The market is growing due to the rising usage of technologically improved products. Increased adoption of advanced diagnostics and patient care devices for better treatment management is expected to promote the growth of the market in the forecast period.

COVID-19 Impact on Asia Pacific Medical Device Contract Manufacturing Market Report

The exclusive COVID-19 impact analysis report by Axiom MRC provides a 360 degree analysis of micro and macro-economic factors on the Asia Pacific medical device contract manufacturing market. In addition, complete analysis of changes on the Asia Pacific medical device contract manufacturing market expenditure, economic and international policies on supply and demand side. The report also studies the impact of pandemic on Asia Pacific economies, international trade, business investments, GDP and marketing strategies of key players present in the market. The outbreak of Covid-19 has a moderate impact on the medical device contract manufacturing market. The demand for medical devices for elective interventions has fallen whereas the demand for medical devices such as ventilators and ventilators has increased due to the COVID-19 pandemic.

Asia Pacific Medical Device Contract Manufacturing Market- Segmental Overview

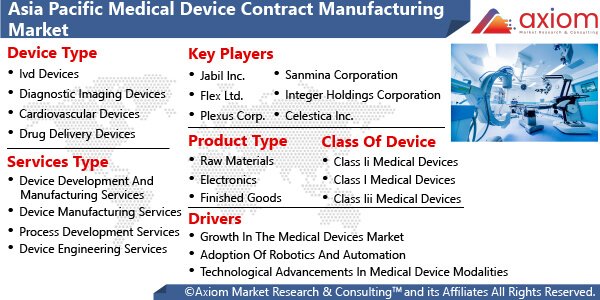

The medical device contract manufacturing market comprises of different market segment like by device type, services type, product type, class of device and country.

Asia Pacific Medical Device Contract Manufacturing Market by Device Type

The Asia Pacific medical device contract manufacturing is available in market according different type including IVD devices {IVD consumables, IVD equipment}, diagnostic imaging devices, cardiovascular devices, drug delivery devices {infusion sets and administration sets, syringes, inhalers, autoinjectors & pen injectors}, orthopedic devices, ophthalmology devices, diabetes care devices, dental devices, endoscopy devices, respiratory care devices, surgical devices, gynecology/urology devices, personal care, neurology devices. An IVD devices is an in vitro diagnostic medical device which includes reagents, reagent products, calibration materials, control materials, kits, instruments, apparatus, equipment, and systems that are intended for use in the examination of specimens taken from the human body to diagnose diseases. Drug delivery devices are specialized devices used for the delivery of a drug or therapeutic agent via a specific part of the body. Such devices are used as part of one or more medical treatments. Orthopedic devices are used to prevent or manage musculoskeletal problems, while orthotics support or straighten weak joints or limbs.

Asia Pacific Medical Device Contract Manufacturing Market by Services Type

The Asia Pacific medical device contract manufacturing has different service such as device development and manufacturing services, device manufacturing services, process development services, device engineering services, quality management services, packaging validation services, inspection and testing services, sterilization services. Medical device development and manufacturing services specialize in a certain process or task and can offer expertise from frequent practice of their manufacturing or services for customers, clients, and inventors of medical devices include product concept and development, process validation and verification, production, or highly specialized manufacturing, packaging. Sterilization services are utilized by the medical technology industry to rid of bacteria on medical and diagnostic devices and other microorganisms.

Asia Pacific Medical Device Contract Manufacturing Market by Product Type

The Asia Pacific medical device contract manufacturing has various product types such as raw materials, electronics, and finished goods. Raw materials, also known as unprocessed materials, are essential components in the production of medical devices and their components. Medical technology manufacturers have access to a wide variety of raw materials, including additives, metals, ceramics, and gels. Pacemakers, defibrillators, drug-releasing pumps, hearing aids, and diagnostic equipment for measuring, monitoring, and recording physiological functions such as heartbeat and brain waves are examples of medical electronic devices. Manufacturers of finished goods/devices who want to sell medical products commercially. Any device or accessory to a device that is set to use or function is referred to as a finished device.

Asia Pacific Medical Device Contract Manufacturing Market by Class of Device

The Europe medical device contract manufacturing market has following class of devices such as Class I, Class II, Class III. Class I devices have less impact on the general health of the patient and do not come into contact with the patient's organs, central nervous system, or cardiovascular system. These devices present minimal potential for harm to the user and are often simpler in design than Class II or Class III devices. A class II medical device is used for the patient that poses a greater risk to patients than a class I. Class III medical device is used with the highest possible risk patients. These devices usually sustain or support life, are implanted, or present potential unreasonable risk of illness or injury.

Asia Pacific Medical Device Contract Manufacturing Market by Country

Asia Pacific medical device contract manufacturing market is studied for the following countries like China, India, Japan and Rest of Asia Pacific among others. The Asia Pacific is expected to grow at fast pace in the forecast period. The major shares of the Asia Pacific region is mainly attributed to the lower cost of raw materials & labor compared to the developed countries. Due to improving healthcare infrastructure, the adoption of technologically advanced products, and the increasing demand for medical devices is propelling the growth of medical device contract manufacturing market in the Asia Pacific region. Also the rising geriatric population and increase in healthcare expenditure is contributing to the growth of the market.

Asia Pacific Medical Device Contract Manufacturing Market Key Player

The key players in medical device contract manufacturing market are Jabil Inc., Flex Ltd., Plexus Corp., Sanmina Corporation, Integer Holdings Corporation, Celestica Inc., Gerresheimer Ag, Te Connectivity Ltd., Nipro Corporation, West Pharmaceutical Services, Inc., Benchmark Electronics Inc., Recipharm Ab, Kimball Electronics, Inc., Nortech Systems Incorporated, Nemera Development Sa, Viant Medical Holdings, Inc., Tecomet, Inc., Smc Ltd., Phillips-Medisize Corporation, Tessy Plastics Corp, Carclo Plc, Nolato Gw, Inc. (A Part Of Nolato Ab), Mehow, Tekni-Plex and Peter’S Technology among others.

Recent Developments:

November 2020, Nipro Corporation (Japan) acquired Venari Medical’s (Ireland) exclusive sales rights for a vascular treatment device developed by Venari Medical in Japan and overseas

October 2020, Nemera (France) acquired Copernicus (Poland) to become a leading patient-centric drug device combination solutions company. This acquisition will bolster the company’s production capabilities and expand its product portfolio

September 2020, Nipro Corporation established its sales offices in Xi'an, Wuhan, Hefei, and Xiamen. The new offices will further strengthen the company’s sales and service network in China to provide more community-based, meticulous services and respond to the needs of the medical scene, thereby enhancing the presence of the “Nipro brand”

January 2020, Nipro Asia Pte Ltd. (Singapore) acquired JMI Marketing (Bangladesh) to secure a large market share in Bangladesh’s rapidly growing economy for disposable medical devices, including infusion sets, syringes, and IV catheters