Antibody development is ideally done in host animal and through additional procedure in lab. The development process of antibody and studies are primary goal for future production of antibody according to different diseases. The process start from gene sequence, hybridoma cells, recombinant vector or stable cell lines for the production of antibody. United States antibody production market is majorly driven by services including monoclonal and polyclonal antibody production services with massive presence of manufacturer across the country. The rising pool of cancer cases and other diseases is expected to propel the demand for the market during the forecast period.

Market Dynamic- United States Antibody Production Market

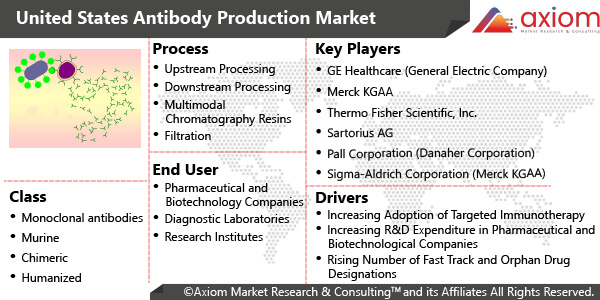

The factor driving the growth of United States market are increasing adoption of targeted immunotherapy as it helps in the improvement of the management and treatment of patient with advanced melanoma. Furthermore, increasing incidence of malignant melanoma in young people has led the requirement for antibody production. Additionally, increasing r&d expenditure in pharmaceutical and biotechnological companies for producing effective antibody for specific disease with cost effectiveness is expected to boost the demand for market during the forecast period. Similarly, rising number of fast track and orphan drug designations is the key factor accelerating the growth of market.

COVID 19 Impact on United States Antibody Production Market Report

The exclusive COVID 19 impact analysis report by Axiom MRC provides a 360 degree analysis of micro and macro-economic factors on the United States antibody production market. In addition, complete analysis of changes on the United States antibody production market expenditure, economic and international policies on supply and demand side. The report also studies the impact of pandemic on global economies, international trade, business investments, GDP and marketing strategies of key players present in the market. COVID-19 had a positive impact on market as the demand for the production of new antibody was accelerated specifically for corona viruses.

United States Antibody Production Market Segmental Overview

The antibody production market comprises of different market segment like process, end user, class.

United States Antibody Production Market by Process

The antibody production includes key process segment of upstream processing, downstream processing, ion exchange (iex) chromatography resins, hydrophobic interaction chromatography (hic) resins, multimodal chromatography resins, and filtration. Further, upstream processing includes bioreactors and consumables. Bioreactors is further sub segmented to large-scale bioreactors and single-use bioreactors (subs). Likewise, consumables includes media and reagents and buffers. Also, downstream processing is bifurcated to chromatography instruments and chromatography resins. Additionally filtration includes filtration systems and filtration consumables and accessories. The downstream processing is expected to lead in the United States market. The downstream processing majorly focuses on the yield and productivity and purity, process capabilities. The processing helps in increasing separation efficiency of single unit operation which is expected to drive the growth of segment. Likewise, upstream processing has rising demand in market due to key factor like cost effective processing, higher yield, efficient facility, and increases the speed of antibody production.

United States Antibody Production Market by End User

The antibody production market finds its end use in pharmaceutical and biotechnology companies, diagnostic laboratories and research institutes. Pharmaceutical and biotechnology companies is anticipated to register major market for the United States antibody production market attributing to massive presence of manufacturer in the country. Besides, rising new drug development, clinical studies, product approval has led the increasing demand for the U.S. market. In addition, research institutes is expected to hold second position in the market. The growing research and studies on different antibody according to disease, growing funding projects, and investment has contributed in the growth of market.

United States Antibody Production Market by Class

The antibody production by class is available in market according to monoclonal antibodies, murine, chimeric, humanized and polyclonal antibodies. Monoclonal antibodies is anticipated to gain major market for the United States antibody production market. The factors contributing in the growth of market are rising demand in segment specifically for producing monoclonal antibodies for different diseases for example COVID-19 which provide the ability to proceed for treatment in patient population. It helps to reduce the burden in hospital and helps the patient to fight off the different disease. Besides, polyclonal antibodies is expected to growth at significant pace during the forecast pace. The segment is expected to witness rising demand owing to increasing cases of cancer across the United States which is likely to propel the growth of market during the forecast period.

United States Antibody Production Market Key Player

The key players in antibody production market are GE Healthcare (General Electric Company), Merck KGAA, Thermo Fisher Scientific, Inc., Sartorius AG, Pall Corporation (Danaher Corporation), Sigma-Aldrich Corporation (Merck KGAA), Eppendorf AG, Cellab GmbH, Integra Biosciences AG and Fibercell Systems Inc. among others.

Recent Developments:

March 2021: Pionyr Immuno therapeutics had collaborated with Lonza to support the oncology product development. The collaboration will bring the Pionyr third pipeline development candidate for novel Myeloid Tuning target to clinical development. Also, Lonza Company will provide cell line development, process development, drug substance and drug product manufacturing for Pionyr’s monoclonal antibody candidate intended for oncology indications.

November 2020: Purolite Ltd had announced that the company will supply its protein A capture resin, Praesto Jetted A50 to WuXi Biologics for immediate use. The WuXi Biologics company will use the Praesto Jetted A50 to provide their customer for affinity chromatography resin for range of downstream processing for monoclonal antibody purification.

October 2020: IAVI and Serum Institute of India had announced an agreement with Merck KGaA, Germany to develop SARS CoV-2 neutralizing monoclonal antibodies (mAbs) and is co- invented by IAVI and Scripps Research as innovative interventions for COVID-19 pandemic.

September 2020: MilliporeSigma had announced the $65 million expansion of its HPAPI and ADC manufacturing capabilities and capacity at its facility near Madison, Wisconsin. The investment will allow the large scale manufacturing of increasingly potent compounds that have potential to treat cancer. The completion is likely to be completed by Mid-2022 and will add approximately 50 full time jobs starting in 2021.